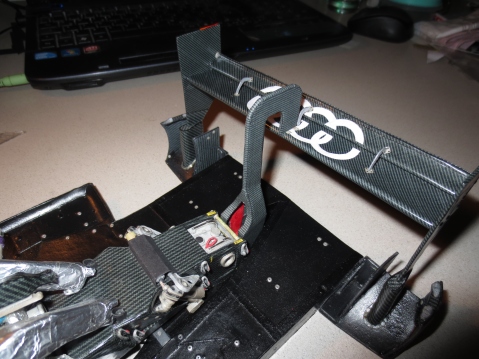

rear wing manufacturing

Here’s another small update on the rear wing manufacturing of the Audi R18. There’s not really much to say about. The regulations dictates a maximum height of the wing of 965mm above the reference plane. The wing itself must be “framed in a volume measuring 250mm horizontally x 150mm vertically x 1600mm transversally” (citation of the ACO TECHNICAL REGULATIONS 2011 PROTOTYPE “LM”P1 – “LM”P2; Page 14). And of course the Audi Sport Team fully exploit these regulations. Additionally a 20mm gurney is mandatory. There are also static load tests for wing, gurney and central wing- support which I won’t explicate.

The endplates must fit into a rectangle of 765mm x 300mm with a minimum area of 1000mm² and a minimum thickness of constantly 10mm and 5mm radiuses at the edges. The maximum height of the EP is same as max. height of the car which is 1030mm above the reference plane.

My rear wing height is not within the regulations. The endplates top edge is about 104mm above the reference plane. I designed the central wing support in a way, that he presses down the wing a bit to get the wing within the regulations.

Measuring the end plate height. It was a bit of a shock when I saw this. Meanwhile I’m working that exactly, that such a mistake takes me wonder. At the Red Bull RB7 there was only 1mm mistake in full length (491mm)! Here is it 1mm in 103mm.

Impressive attention to detail!

LikeLike

Thanks 🙂

LikeLike

Nice work Paul! One possible slight correction for you. I believe TDI actually stands for Turbocharged Direct Injection. It harks back to the first VW TDI engines that had direct injection rather than indirect injection. Just a slight technical hitch! (Having read VW and Audi service manuals….)

LikeLike

Okay, that can be. I took it out of the german Wikipedia (because I was too lazy to look on the Audi HP) and there it’s defined as Diesel as well as Direct. But if it’s called Direct Injection in the Audis manual that should be correct. 😉 Thanks!

LikeLike

No problem, just a minor detail!

LikeLike

this is incredible, all from paper? wow

LikeLike